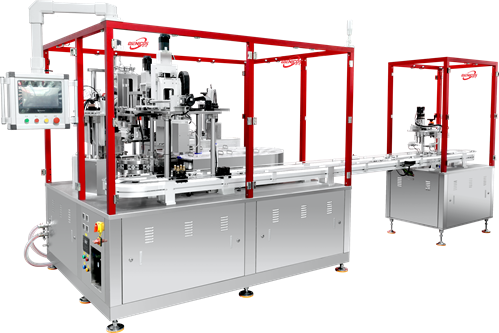

1200pcs per hour lipstick production machine from GIENICOS

| Dimension : | |

| Voltage : | 3P.380V |

| Power : | |

| Working pressure : |

█Equipment List

● Lipstick Main machine 1unit

● Lipstick filling machine 1unit

● Molds come with the machine(List as below)

- Silicone rubber mold 112pcs

- Grasper 1 set(4pcs)

- Regular lipstick container base 16 pcs

1.Frame

- Safety cover adopts Aluminum base, surface steel material Chrome-plated treatment.

- Table covered with SUS, Electric Cabinet and door are SUS.

- Equipped with fixed holding feet. Material loading station can be removed and carried.

- Euro Standard Aluminum profile column

- Stainless steel door

2. Table Drive System

- Imported Tech of U-shape Circulation Slide Railsystem, 28sets precision mold for silicone rubber

(anodized processing)

- Station Lifting Controlled by servo index

- Dynamic Part Full Sealed, cooling area has two layer insulation and sealed.

3. Pre-heating device

- Moulds pre-heating by 2 units Leister heater, blow rate and heating rate are adjustable.

- Cylinder control the heater’s moving up/down.

- Heater height control by hand wheel

- Heating time control by timer

- Temperature digital display, PID display (with Air Fan, speed control)

4. Filling machine (1unit)

- Moveable Filler (2 Nozzle), Servo motor to to individual control each nozzle’s filling volume; 2nd mixing function.

- Two 30L Tank, outer cleaning system.

- Fast-joint Piston pump

- 2nd Nozzle pre-heat, bulk collection function.

- Tank with ceramic heating function, precise control the bulk temp.

- Adopts electric heating dual layer hose to transfer bulk, change inner hose when customer change color.

- Servo motor driven piston pump.

- Cylinder control niddle valve’s switch

- AC motor drive the stirrer

- PLC control Electrical system

- Control part compose of touch screen and buttons.

- Power supply is possible from a connector located on the machine or a separate power connector in the melter storage area.

5. Nozzle moving system

- Air Cylinder control nozzle on/off

- Air Cylinder control nozzle backward/forward

- Heating tube heat the nozzle

- SUS material bulk collect tray

- Air cylinder control the horizontal moving of material.

6. Re-heat Device

- Consists of LEISTER(Import from Switzerland)

- Heater height control by hand wheel

- Temp.setting on touch screen, fan volume adjust manually.

7. Cooling Unit

- Separated water circulation type cooling device.

- Temperature range max -20℃。

- 8Hp compressor

- Digital temperature control and display.

- R404A refrigerant freon gas

- Cooling tunnel installed underneath table.

- Adopt pipeline circulate the cold air.

- Dual layer insulation material outside the cooling tunnel.

8. Discharging Unit

- High Precision Industrial Module control the movement of Y/X direction and lifting up/down.

- Grasper the container 4pcs.

- Servo Motor control the grasper’s rotating.

- Air Cylinder control the vacuum system’s lifting up/down.

- Two-jaw structure vacuum system to release lipstick out of the silicone moulds. Grasper is changeable(Self-patent). No need change vacuum station when the lipstick size within 8mm-17.1mm(diameter). Grasp tense is adjustable.

- Flexible chain type conveyor to transfer lipstick container mold.

9. Screw Down Unit

- Air cylinder control the grasper’s on/off.

- Servo motor control the grasper’s rotating.

- Torque control the lipstick rotating and falling down.

█ Charateristics

1. Application – Lipstick (Regular, Slim or Mini Type)

2. Production Capacity – 1000 ~ 1,300 PCS/HOUR。

3. Operator – 2 people (Only 1 people after mount with robot)

4. Power supply

- 3phade 5 wire - 380V/ 50-60HZ/ 3 PHASE & MAX.23KW

- Air supply – 0.6 MBAR above

Tel: +86-21-39120276

+86-13482060127 (Holiday Hotline)

E-mail: sales@genie-mail.net

Headquater: Room 101, No 265,Lane 99,Xiang Ju Road,Zhao Xiang Town,Qingpu District, Shanghai

Factory: No.2 Southern, Chansi Road, BanQiao Economic Development Zone,Taicang,Suzhou,China